Japan’s urban transit hubs are redefining renewable energy generation in the most human way possible, through footsteps. Piezoelectric floors installed at Tokyo and Shibuya Stations convert the pressure of millions of daily commuters into measurable electrical energy.

While the concept has been field-tested in stations, quantifying its real-world output provides a grounded view of its potential and limits.

Using operator ridership reports and JR East trial documents, this article quantifies station-floor output, maps it to practical loads, and contrasts it with highway-grade piezo systems.

The Physics of Piezoelectric Floors

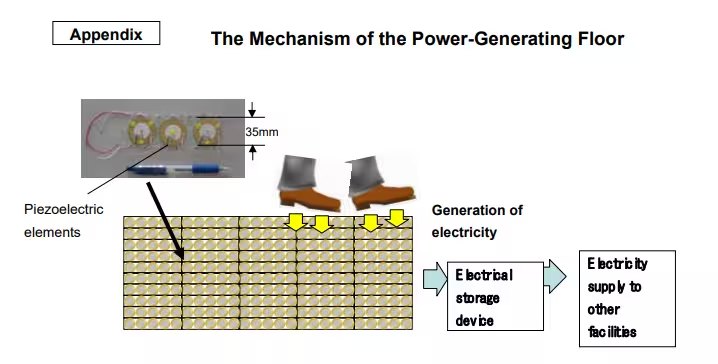

Piezoelectric materials produce an electric charge when mechanically stressed, a phenomenon discovered by the Curie brothers in 1880. In Japan’s installations, these materials are embedded beneath durable floor tiles. Each step compresses ceramic discs (about 35 mm in diameter), deforming their crystal lattices and producing a small voltage.

This energy is then rectified and stored in capacitors for immediate or later use. This approach was demonstrated at Tokyo Station in January–March 2008 with an installation around 90 m² that targeted about 500 kW·s per day and ~1 W·s per passenger as documented in JR East’s public trial materials.

In JR East’s station-floor trials, the measured energy per passenger was about 0.1 W·s (watt-second) in 2006; about 1 W·s in the January–March 2008 test at Tokyo Station; and the December 2008–February 2009 trial targeted 10 W·s per passenger after improvements to element layout, pressure-transmission, and circuitry.

Counting Footfalls: Tokyo and Shibuya by the Numbers

Energy output depends directly on pedestrian traffic. Operator-reported FY 2024 daily passengers (definitions differ by operator):

| Station × Operator | Metric (operator definition) | FY 2024 Daily Passengers |

|---|---|---|

| Tokyo – JR East | Boarding passengers only | 434,564 |

| Tokyo – Tokyo Metro | Entries & exits (Metro) | 199,232 |

| Shibuya – JR East | Boarding passengers only | 324,414 |

| Shibuya – Tokyo Metro (all Metro at Shibuya) | Entries & exits (Metro) | 751,998 |

| Shibuya – Tokyu (Tōyoko Line) | Entries + non-pass users; includes through-service counts† | 414,186 |

| Shibuya – Tokyu (Den-en-toshi Line) | Entries + non-pass users; includes through-service counts† | 604,246 |

| Shibuya – Keio (Inokashira Line) | Entries & exits | 286,940 |

Using JR East’s 1 W·s per passenger benchmark from the January–March 2008 test, multiply the per-operator counts above by 1 J per passenger to get indicative daily joules (1 J = 1 W·s), then convert to kWh. This keeps assumptions aligned with the only station-floor value JR East published for that period.

For January–March 2008, JR East expected 500 kW·s/day, equivalent to a 100 W bulb for about 80 minutes. A later December 2008–February 2009 installation (~25 m²) targeted ≥ 1,400 kW·s/day, following design upgrades.

What Can Footstep Power Actually Do?

The numbers reveal the challenge: even millions of steps produce less than one kilowatt-hour per day, hardly enough for heavy infrastructure. Yet within this constraint, several practical and symbolic uses emerge.

1. LED Signage and Digital Panels

Small LED boards consume about 30–40 W each. Shibuya’s 0.6 kWh daily output could power two mid-size LED displays for roughly 10 hours. JR East’s trial in 2008 used this approach to light digital signboards near ticket gates, demonstrating effective micro-power deployment.

2. Ticket Gates and Vending Machines

Automatic ticket gates typically draw 120–150 W. The energy from the Tokyo floor could operate one gate for only ~2 hours, illustrating that the system’s role is supplementary rather than standalone.

3. Smartphone Charging Potential

A standard smartphone battery stores about 10 Wh (36 kJ). Shibuya’s daily output of 2.2 MJ could theoretically charge around 60 phones per day, though conversion losses would reduce that figure.

Engineering Gains: From Durability to Power Density

JR East’s project evolved through key phases:

- 2006 pilot (Marunouchi North Gate, ~6 m²) peak ~10,000 W·s/day; output declined after ~3 weeks due to durability.

- Jan–Mar 2008 demo (Yaesu North Gate, ~90 m²) goal 500 kW·s/day and ~1 W·s per passenger (≈10× vs. 2006 per-area), with “high-density elements” and revised storage.

- Dec 2008–Feb 2009 (~25 m²) targeted ≥ 1,400 kW·s/day; improved element shape/placement, pressure-transmission, circuits, and swapped the walking surface from rubber to stone tiles used in stations.

JR East’s technical note also provides photos, a simple schematic, and the 35 mm piezo element detail, clarifying the stack-up, storage path, and targeted durability improvements across the three station trials.

Recent material studies show promise for higher efficiency:

- Modern piezoelectric composites (lead-free ceramics and PVDF polymers) achieve up to 11–13 W/m² under optimal conditions.

- Advanced highway modules tested by the California Energy Commission (CEC) target 333 W/ft² (~3,584 W/m²), projecting 72,800–907,873 kWh/year per mile of roadway and up to 300 t CO₂ reductions annually.

If Tokyo Station’s 25 m² area achieved this highway-grade energy density, it could generate ~2,150 kWh/day, a theoretical 15,000× increase over the 2008 trial. Such a leap remains speculative and contingent upon breakthroughs in material strength and efficiency.

Comparative Context: Footstep Floors vs. Highways

| System Type | Reported metric | Source-aligned figure |

|---|---|---|

| Tokyo Station floor – Jan–Mar 2008 (~90 m²) | Total daily energy | 500 kW·s/day |

| Tokyo Station floor – Dec 2008–Feb 2009 (~25 m²) | Total daily energy | ≥ 1,400 kW·s/day |

| Roadway modules (highway traffic) | Target power density and annual energy per mile (1 lane) | 333 W/ft²; 72,800–907,873 kWh/year (light vehicles → heavy trucks) |

For context, highway-grade piezo modules operate under vehicle axle loads rather than footfalls; one state-level program projects roughly 333 W/ft² device power density and about 72,800–907,873 kWh per mile-lane annually, which is not comparable to pedestrian floors but illustrates the effect of load magnitude.

This contrast underscores a core engineering truth: energy harvested depends primarily on the magnitude of mechanical stress. A human step (≈ 700 N) delivers several orders of magnitude less energy than a truck axle load. Pedestrian systems are thus best classified as micro-generation, suited for low-energy applications like lighting, sensors, or interactive installations.

Beyond Power: Public Engagement and Smart-City Integration

Though modest in power, piezoelectric floors offer significant educational and data-gathering value. Commuters visibly contributing to a shared energy display strengthen public awareness of sustainable design. Many installations, such as those by the UK-based company Pavegen, now integrate footfall analytics to inform crowd management and environmental monitoring.

In Japan, future iterations could integrate with IoT-based smart infrastructure, enabling localized power for Wi‑Fi sensors, air‑quality monitors, or emergency beacons, turning everyday movement into part of an intelligent energy microgrid.

In operational deployments, pedestrian tiles can surface real-time footfall and energy analytics to inform crowd management and public engagement in high-traffic zones.

Key Takeaways

- JR East’s Jan–Mar 2008 station-floor test targeted ~500 kW·s/day (≈100 W for ~80 minutes).

- A later Dec 2008–Feb 2009 installation targeted ≥ 1,400 kW·s/day after design upgrades.

- Compared to vehicular systems, pedestrian floors yield thousands of times less energy, yet they excel as tools for public engagement, data collection, and sustainability awareness.

- Ongoing advances in material science and hybrid energy harvesting could transform footstep energy from novelty into a functional component of urban power networks.

Conclusion

Japan’s piezoelectric floors demonstrate a striking fusion of human motion and renewable power. While their electrical yield remains small, their symbolic and technological value is substantial. They prove that even the smallest actions, like a daily commute, can contribute to a city’s renewable vision.

As materials evolve and integration deepens, these tiles may one day move from lighting a signboard to powering the infrastructure beneath our feet.