Inversion Space has transitioned from a 25‑person garage startup to one of the most closely watched new entrants in the orbital logistics sector. Founded in Los Angeles in 2021 by Justin Fiaschetti and Austin Briggs, both former propulsion engineers.

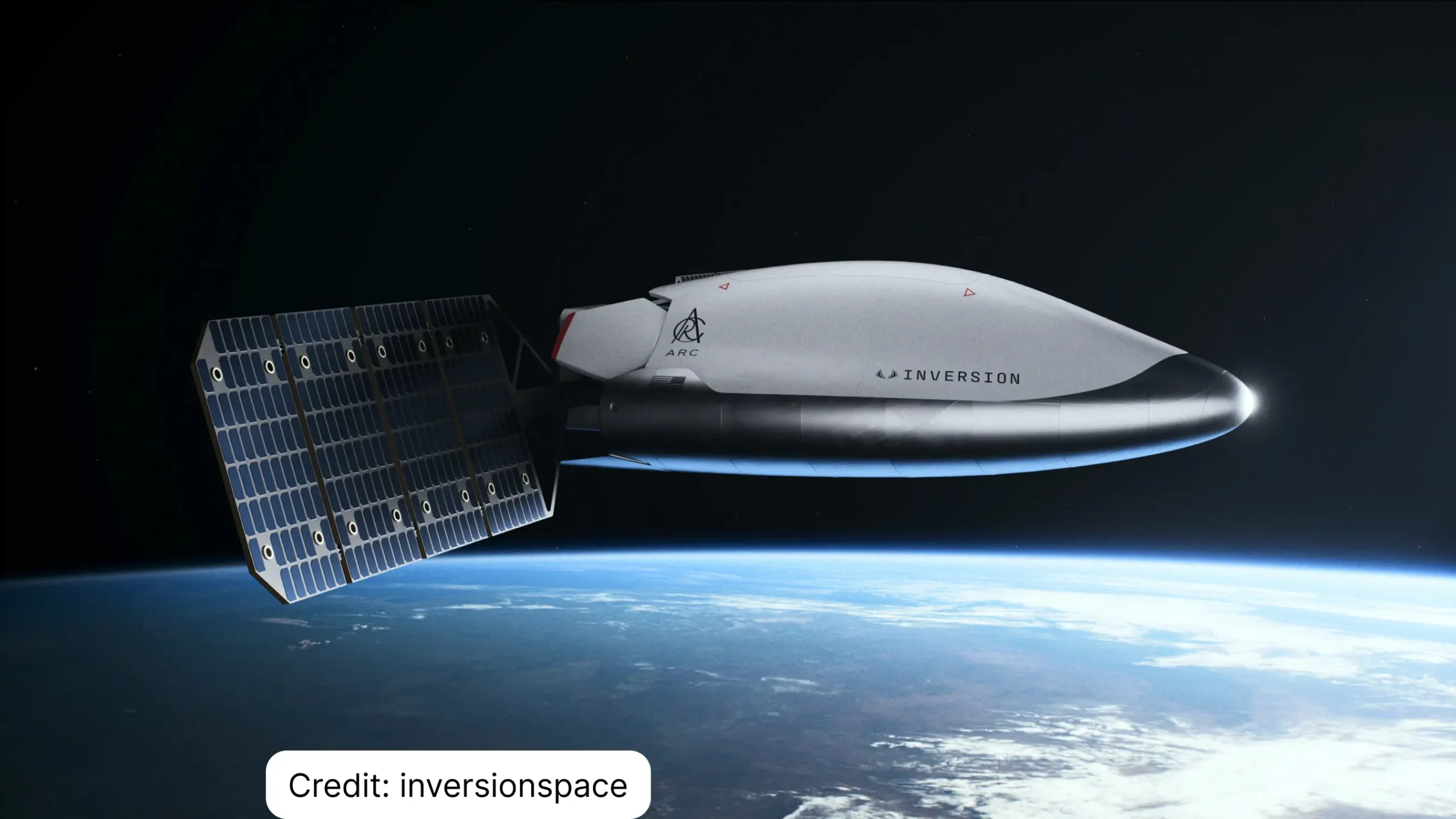

The company’s mission is straightforward yet ambitious: to make space the fourth domain of transportation, alongside land, air, and sea. Their flagship spacecraft, Arc, is a reusable reentry vehicle designed to deliver mission-critical cargo and effects to anywhere on Earth in under an hour.

This milestone builds directly on Ray, Inversion’s minimalist test platform developed by a 25-person team for under $1 million. Ray’s low‑cost validation of avionics, propulsion, and separation systems provided the engineering foundation for Arc’s design.

Ray: A Minimalist Spacecraft with Maximum Impact

Why Ray Was Built

Ray was a technical demonstrator built to validate Inversion’s in-house hardware and software stack in orbit.

The Lean Engineering Philosophy

The spacecraft embodied the company’s “lean aerospace” model, extreme cost efficiency, vertical integration, and fast iteration. Over 90% of Ray’s avionics and ground stack were developed internally, and the vehicle included Inversion’s CE-1 deorbit engine. This approach shortened development cycles and gave engineers full control over integration and testing.

Flight Heritage and Lessons Learned

Ray launched to orbit in January 2025 on a rideshare mission and validated key subsystems, including avionics, solar arrays, propulsion, and an in-house separation system.

While Ray’s ignition system failed during its planned deorbit burn, caused by a transistor overcurrent, this anomaly produced valuable telemetry that improved Arc’s propulsion electronics. Instead of treating the mission as a loss, Inversion continued using Ray for long‑term software testing in orbit, demonstrating resilience and iterative learning.

Key Technical Highlights (Ray)

| Subsystem | Function | Outcome |

|---|---|---|

| Avionics | Custom software stack controlling GNC and telemetry | Validated autonomous operations and on‑orbit software updates |

| Propulsion | CE-1 deorbit engine, 8 lbf thrust. | Ignition failure led to a system redesign for redundancy |

| Thermal Protection | NASA Ames provided C-PICA and SIRCA; no reentry test. | Verified material performance pre‑flight; no reentry test conducted |

| Separation & Parachute Systems | Proprietary deployment + supersonic parachutes | Mechanically verified; reused in Arc’s design |

Ray’s success lay not in perfect performance but in risk retirement, de‑risking Arc’s architecture through validated data and inexpensive iteration.

Subsystems Breakdown: Ray to Arc

- Avionics and Software: More than 90% of Ray’s flight and ground software was written internally; Arc builds on that architecture with AI-assisted GNC and computer-vision-based landing guidance intended for precision landings.

- Power and Communications: Ray’s solar arrays maintained power margins above requirements during on-orbit ops. Arc’s arrays scale this system, designed for up to five years of orbital standby, enabling pre‑positioned vehicles ready for on‑demand deorbit missions.

- Propulsion Improvements: Following Ray’s ignition-system fault, Arc advances the propulsion system; specific design changes are not publicly detailed. The thruster layout and reaction control system (RCS) allow fine orbital maneuvers and pinpoint atmospheric targeting.

- Separation and Recovery Systems: Ray’s proprietary separation mechanism achieved clean release from Falcon 9, informing Arc’s modular design, adaptable to multiple launch vehicles. Arc uses an actively controlled parachute system able to steer, maneuver, redirect, and softly touch down, demonstrated in autonomous precision drop testing, with landings within 20 feet (≈6 m) claimed by the company.

- Thermal Protection Partnership with NASA: Under a NASA Space Act Annex, NASA Ames provides aerothermodynamics analyses, access to the FIAT ablation/thermal-response model, and support for TPS materials, including Conformal PICA, HEEET, and SIRCA for Arc.

Scaling Up: From Demo to Flagship

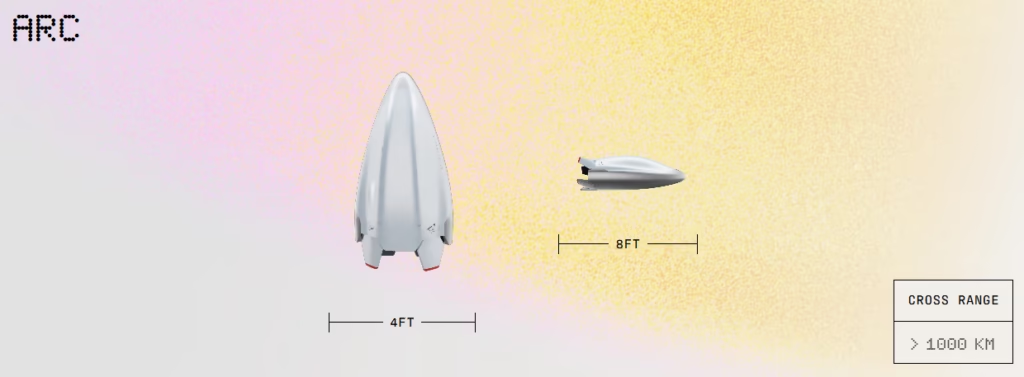

Arc scales to a lifting-body spacecraft ~8 ft × 4 ft with cross-range >1,000 km during reentry, enabling long-distance lateral targeting.

Mission Capabilities

Arc supports three mission types:

- Rapid Cargo Delivery: Arc vehicles can be pre-positioned in low-Earth orbit and operate on-orbit for up to five years, then deorbit on demand for under-an-hour delivery to target areas.

- Hypersonic Test Platform: Arc provides extended time on condition during reentry, including maneuverability at Mach 20+, and is slated to support testing under MACH-TB 2.0.

- Orbital Logistics: Arc is designed for rendezvous, capture, and redeploy operations to support on-orbit servicing.

Design Evolution Summary

| Parameter | Ray | Arc |

|---|---|---|

| Diameter / Dimensions | 20 in (0.5 m) | 8 ft × 4 ft (2.4 × 1.2 m) |

| Mission Type | Technology demonstrator | Operational reentry vehicle |

| Payload Capacity | N/A | (not publicly specified) |

| Landing Type | Ocean splashdown (planned) | Precision land landing (within 20 ft / ~6 m). I aligned with that and cited the company’s press release.) |

| Reusability | Single‑use | Fully reusable |

Manufacturing & Testing Milestones

- Full‑Scale Development Unit: By October 2025, Inversion built a full-scale manufacturing development unit of Arc’s main structure and completed dozens of drop tests to refine accurate landings.

- Aerodynamic and TPS Validation: In partnership with NASA, Inversion is receiving aerothermodynamics analyses and TPS design/verification support for Arc via the Space Act Annex, including FIAT model access and TPS material support.

- Facilities and Infrastructure: Inversion operates a 55,000 ft² Los Angeles headquarters with integrated manufacturing and clean-room spaces, plus a 5-acre Mojave Desert test site for engine and recovery testing.

Looking Toward 2026: From Prototype to Constellation

First Mission Plans

Arc’s first orbital mission is scheduled for 2026, and Inversion announced a $71 million SpaceWERX STRATFI award supporting development of its autonomous reentry vehicles. The company notes partnerships with organizations such as the U.S. Space Force and NASA.

Market and Strategic Outlook

Success would position Inversion as a key player in on‑demand global logistics, complementing traditional supply chains and enabling rapid response in defense, disaster relief, and scientific return missions. Over time, Inversion envisions constellations of Arc vehicles positioned in orbit to provide global, on-demand delivery.

Startup Culture and Broader Implications

Inversion’s rise exemplifies a wider lean aerospace trend: small, agile teams using in‑house design and rapid testing to challenge long development cycles. Building a functional orbital spacecraft for under US $1 million redefines the entry barrier for advanced space systems, an approach increasingly mirrored by new aerospace startups worldwide.

Conclusion: A New Model for Space Logistics

From Ray’s modest beginnings to Arc’s operational promise, Inversion has demonstrated how disciplined engineering and iterative design can yield real progress in orbital logistics. Ray’s mission validated the fundamentals, avionics, propulsion, separation, and TPS, all built on a shoestring budget.

Arc scales those lessons into a reusable vehicle designed to deliver payloads from orbit to any point on Earth in under an hour. If Arc’s 2026 mission succeeds, Inversion will have proven that space can serve as a functional logistics layer, not just a communications platform.

The transition from experimental testbed to transportation infrastructure represents a pivotal moment for both commercial and defense applications, and potentially the dawn of a truly global delivery network that begins in orbit.